Ancon has made a simple improvement to one of its smallest, but most utilised, stainless steel building components to benefit installers of its masonry support systems.

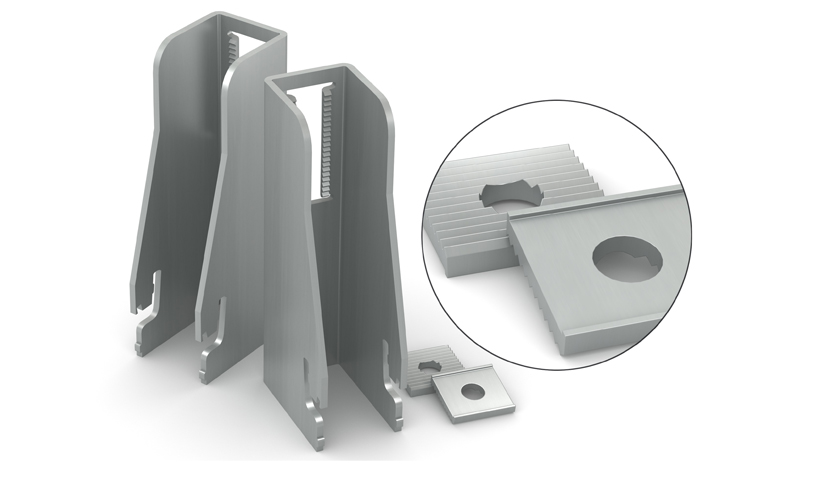

An orientation guide, in the form of two horizontal square ridges, has been incorporated into the design of the classic serrated washer that Ancon supplies with its masonry support brackets.

The square ridges, added to the back of the washer, correspond to the line of the serrations on the opposite side that faces away from the user during installation.

The new design makes it quicker and easier for installers to orientate the serrated washer correctly. Users do not need to view the serrated face before installing the washer and can quickly identify how best to correct any rotation that may occur as the fixing bolt is tightened.

The improved design also enables site supervisors to verify the correct orientation of washers along a line of installed brackets with a quick visual check.

The method by which Ancon masonry support is fixed to a structural frame is simple, safe and reliable, and provides vertical adjustment in 3mm increments.

A deep serrated slot in the back of Ancon support brackets provides valuable vertical adjustment in the final fixing position of the masonry support angle, to accommodate tolerances on site. The serrations on the bracket interlock perfectly with the serrated face of Ancon’s washers, to prevent slip in the line of the load. The correct installation of masonry support systems is essential to the overall stability of a brick façade.

Ancon is a three-time winner of the prestigious Queen’s Award for Enterprise, twice in the Innovation category, and encourages its specifiers and users to provide feedback on how its current product range could be improved or expanded.