Specifiers in Scotland having to deal with what are often very challenging climatic conditions and onerous regulatory requirements on energy performance, are increasingly turning to the use of Thermoblock, manufactured by Marmox Limited and the load-bearing product’s ability to tackle the issue of cold-bridging. The composite 600 mm long units, available in different widths, offer a unique solution to maintaining the structural capacity of walls, supporting loads from upper levels, while preventing heat having a direct pathway out through the building envelope: thus cutting losses and avoiding penalties in calculating a building’s overall performance.

Following the EU’s Energy Performance and Buildings Directive, The Building Standards for Scotland (Section 6) – along with all other building regulations in the UK and Ireland – now state the following: “The building fabric should be continuous over the whole building envelope and be constructed so there are no reasonably avoidable thermal bridges in the insulation layers caused by gaps in the various elements.”

Specifiers in particular want to avoid having to adopt a default y-value of 0.15 W/m2 /K in the SAP calculation which can result in non-compliance and prefer to make use of the Scottish Accredited Construction Details (2015) offering far less punishing figures. Significantly better y values even than the ACDs can be used in the calculations by using Marmox Thermoblocks. Crucially Marmox Thermoblocks have been thermally modelled by the BRE to provide psi values and temperature factors which can be employed in SAP, SBEM and other assessments. The BRE Scheme, called “Certified Thermal Details and Products Scheme” details various wall to floor junction details and is free to download.

Although in Scotland, the most popular application of Thermoblock is beneath the sole plate of a timber frame wall, they are also frequently used beneath block walls, steel frame walls, party wall junctions and door thresholds or around eave junctions with walls and at the base of parapets.

One architectural practice to have already utilised the practical and innovative Marmox solution is Fife based Montgomery Forgan Associates, specifying Thermoblock for a variety of project types across Scotland. Architect Joe Narsapur explained: “We have been specifying Thermoblock for probably five years now in response to being asked to detail cold-bridging solutions where it is required by Building Standards, councils in particular are asking for it and the first large project where we have seen the product used is for the new swimming pool and leisure building on the Clayton Caravan Park near St. Andrews. Thermoblock was the first product we became aware of that offers the high load-carrying capabilities through the incorporation of miniature concrete columns within an insulation. I think it will get used more and more in the future.”

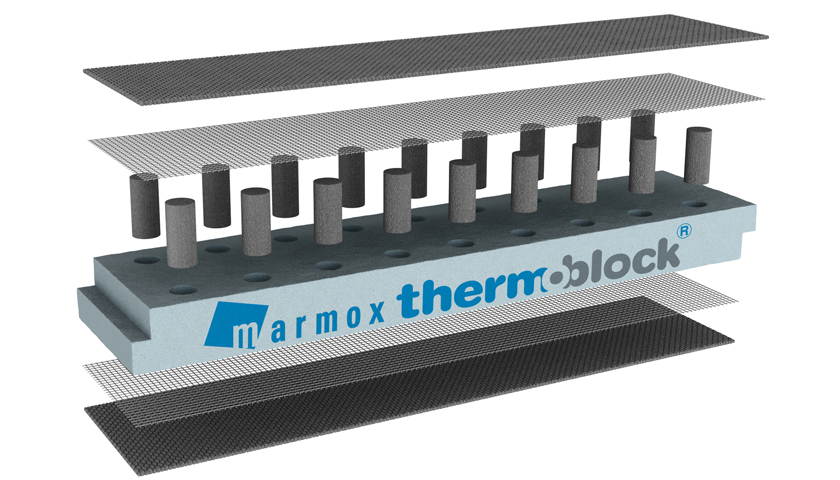

Thermoblocks are available in widths of 100, 140 or 215mm and are formed from sections of XPS (extruded polystyrene) encapsulating two rows of high strength, epoxy concrete mini-columns. These are attached at either end to the top and bottom layers of glass-fibre reinforced polymer concrete, to ensure a good bond with the rest of the structure.

Overall, Thermoblock offers a practical, economic and fully accredited answer to combating cold bridging for different types of development across Scotland, from social housing to schools and commercial properties.