As an independently tested, proven-in-practice and versatile construction material, Membrane WP from the FireflyTM range is ideally suited for use within facade build-ups and other wall constructions, where it will offer weather as well as fire protection while allowing moisture vapour to be vented from the structure. Developed in Australia and used worldwide, FireflyTM Membrane WP is manufactured in the UK by Lancashire based TBA Protective Technologies, while it has been certified as Class A2 Non-Combustible under the challenging EN 13501-1 standard by industry renowned Warrington Fire laboratories. This means the membrane will not support a flame, propagate smoke, toxic gases, flaming droplets or particles and has achieved a rating of A2, s1, d0.

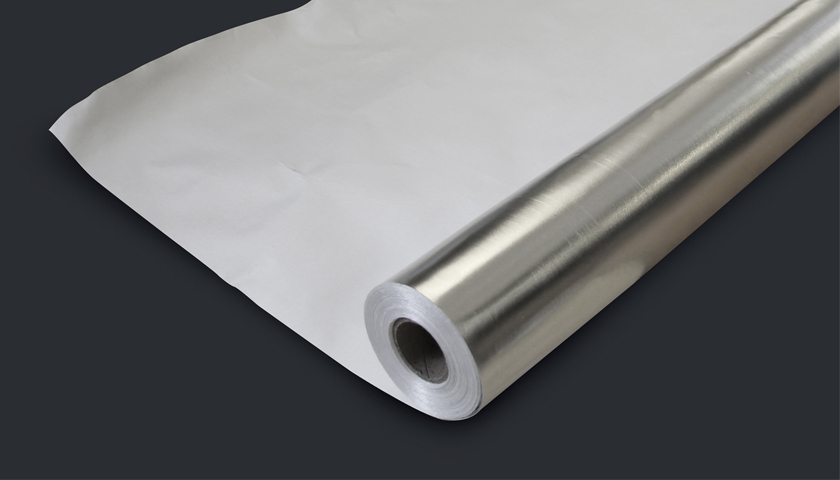

FireflyTM Membrane WP is supplied in 50 metre-long, 1.25 metre wide rolls with a nominal 0.2mm thickness, woven glass substrate which is aluminised on one side. It is both strong and light to handle, weighing just 14 kg per roll. Although the membrane must be protected from accidental damage during storage and not left exposed to the elements for long periods after installation, it has been tested to withstand wind loadings equivalent to the UK’s most challenging climatic conditions. Installation should be carried out in horizontal bands from the lowest level upwards and fixed to supports at 600mm centres, allowing 150mm overlaps that are secured using FireflyTM Aluminium Tape. The product is easy to cut on site, allowing it to be folded back into door and window reveals around the building envelope, where it should again be sealed down with the Aluminium Tape, which can also be used to repair small punctures or tears.

Ideal for use in commercial facades, apartment developments and modular construction, TBA Protective Technologies offers specifiers and contractors, including fire consultants, a full technical advisory service, as well as on-line product information to support this high performance, fully breathable product.