Gravity Cast Iron Drainage Systems for high-rise developments demand strength, acoustic performance, fire safety and long, maintenance-free life, while walk-in showers and wet rooms require new solutions. Mike Rawlings, Marketing Manager for Saint-Gobain PAM outlines a new low connection multi-waste manifold and explains why cast iron should be the material of choice for such developments.

Young, aspirational professionals are moving back into city centres and, with spatial limitations, urban skylines are transforming with the development of more high-rise buildings. These are often mixed-use developments with shops or commercial space on lower floors and residential above. People are paying huge sums to live luxurious lives high above noise and disruption.

Spatial pressure is having another effect on building design. Squeezing more floors into a building can result in less space between floors and smaller ceiling voids in which to fit services. Combined with the trend towards walk-in showers and wet rooms and there’s simply less space for the necessary waste water connections.

Manufacturers are developing new solutions to meet such demand; cast iron has always met the functional and safety requirements of high-rise living, and having invested in 3D printing, PAM can now quickly develop solutions for changing specifications.

Rapid prototypes can be developed in a matter of days, by producing a resin model, then using it for a cast iron prototype. This was instrumental in the development of Saint-Gobain PAM’s new low connection multi-waste manifold, which will be launched in late January.

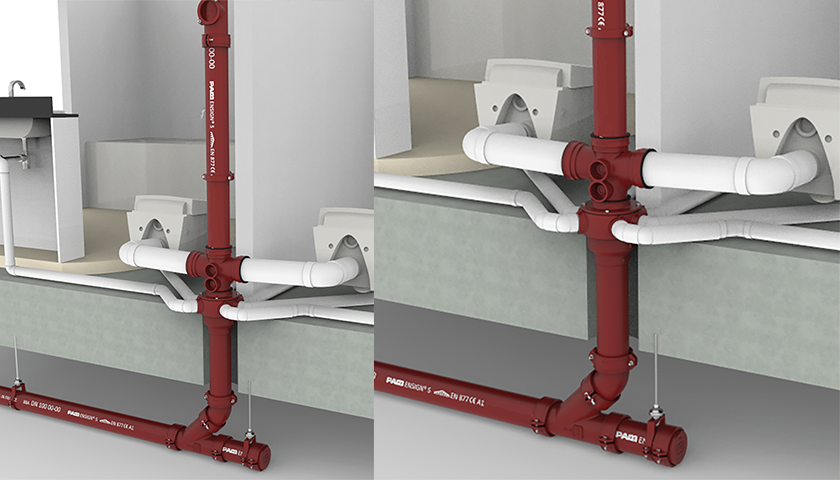

The new low connection multi-waste manifold are available initially in 100mm diameter, closely followed by 150mm diameters by the end of March. The fittings offer up to six 50mm/2” BSP waste inlets and have been flow rate tested by CRM Rainwater Drainage Consultancy. The 100mm unit has been tested to a vertical flow of 1.8 l/s, consistent with a 6 l/s WC flush, and all six 2” waste inlets at a flow of 1 l/s at the same time. The manifold has an internal baffle to eliminate cross flow.

Designed for easy installation, the 2” waste inlets comfortably fit in the ceiling/floor area and an extended spigot accommodates a floor slab of up to 400mm without the need to make connections. The spigot has 10mm cut marks to make it simple to cut to length. Both the 100mm and 150mm diameter manifolds minimise the core hole diameter, fitting into 200mm or 225mm holes respectively.

The new cast iron low-waste connection manifold is available in both the Ensign range with mechanical joints and the fast installation EEZI-FIT range with push-fit connections to product standard BS EN 877.

High-Rise Choices

Given that cast iron systems meet all the requirements of high-rise living, it should be the first-choice material for a drainage system.

Acoustically, cast iron is by far the quietest material for drainage when tested to BS EN 14366:2004, by up to 8dB(A) compared to the best acoustic plastic systems. Further independent tests by TVVL Consultants in Holland – which better mimic real-life situations where the pipe offsets or changes direction – support this.

Saint-Gobain PAM cast iron systems are A1 fire rated for EN 13501-1:2007+A1:2006. It won’t fuel a fire, emit toxic smoke or sooty smog and unlike HDPE won’t drip molten droplets – a vital consideration, particularly in high-rise buildings.

Gravity Cast Iron Drainage Systems for high-rise developments demand strength, acoustic performance, fire safety and long, maintenance-free life, while walk-in showers and wet rooms require new solutions. have always provided a greater level of comfort thanks to superior acoustic performance and being safer in the event of a fire. With the development of new mechanically-jointed or push-fit fittings, cast iron should be the material of choice throughout the high-rise, from basement to penthouse!